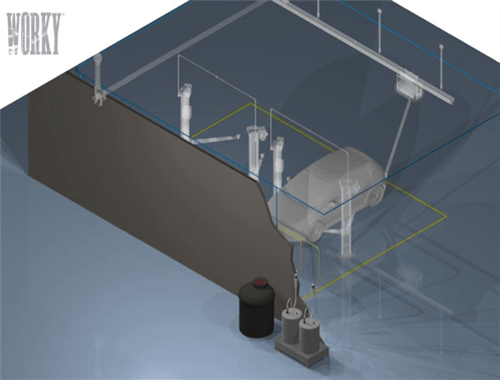

WORKY designs lubrication systems tailored to your workshop: customisation is key to obtaining a configuration set to:

- Actual technical fluid consumption

- Number of utilities

- Plant size.

According to the needs resulting from the combination of these 3 factors, we provided different lubrication systems, explained below.

Lubrication system tailored to your workshop

Based on your workshop's needs, we follow every aspect of fluid distribution, starting from the choice of tanks for the oil room:

Double wall tank, with 1000 or 1500 lt oil capacity. The internal tank is made of polyethylene and the external casing made of stainless steel to guarantee resistance and durability. A built-in leak sensor indicates any fluid leaks from the internal to external camber.

- 3000 lt tank, with containment basin in the event of leaks.

- Barrel tanks for 2 or 4 200 lt barrels; these are certified tanks that meet D.M. 133, 18/05/1995 on liquid containment.

The heart of the system is thus made up of the pneumatic pumps, with piston or double membrane, compatible with all WORKY tanks. WORKY technicians study the viscosity of the fluid to be distributed and the size of the plant and can recommend the right ones for your workshop.

Used oil and fluid distribution parts

To store used oil, the WORKY range includes specific products: this is a 500 lt vertical cylinder, stand-alone, with a non-toxic stabilised U.V. polyethylene frame to protect the content against reactions caused by the elements. The double tank increases safety and containment capacity, and a sensor in the gap monitors leaks.

Lastly, your custom lubrication system can be completed with:

- Electric panels to check the level of fluid or new oil in the tank, with bubble alarm.

- Panels with level gauge for used oil, that prevent overflows before the tanks is full.

Constantly monitored consumption thanks to QAM monitoring

You can never have enough safety and efficiency; to this end WORKY also allows you to supplement your ideal configuration with an advanced QAM monitoring system.

Solenoid valves and litre meters are installed on oil and fluid distribution points; at the same time, a computerised systems saves and manages all data concerning fluid distribution. The advantages are clear: no more waste nor uncontrolled sales and oil consumption. Billing becomes simple, accurate: it exactly corresponds to that distributed.

To learn more about our lubrication systems or ask for a custom estimate, contact us: our engineering department will give you all the help you need.