The production of fumes due to sheet metal welding is, unfortunately, a constant in many industrial environments. The only way to prevent this from happening is to equip the workstations with fume extractors, capable of extracting the emissions at source. We are therefore talking about localised extraction.

How is it best to extract them?

WORKY fume extractors: fixed and mobile systems

To ensure the best quality localised extraction, WORKY has developed two lines of fume extractors: the first is made up of fixed, and the second of mobile units.

Fixed systems

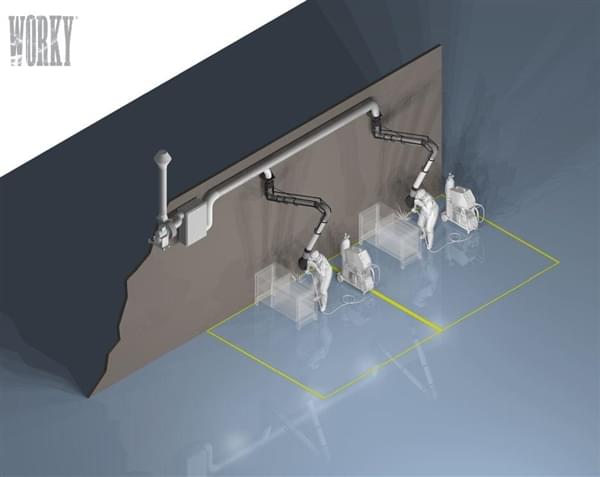

Fixed systems for localised fume extraction require permanent installation. Depending on the specific need, fumes can be captured through:

- wall-mounted or sliding articulated arms,

- hoods

- fume extractor benches.

It is then necessary to install a galvanised pipe inside which the fumes are conveyed - thanks to an electro-extractor - and then expelled outside if they cannot be filtered.

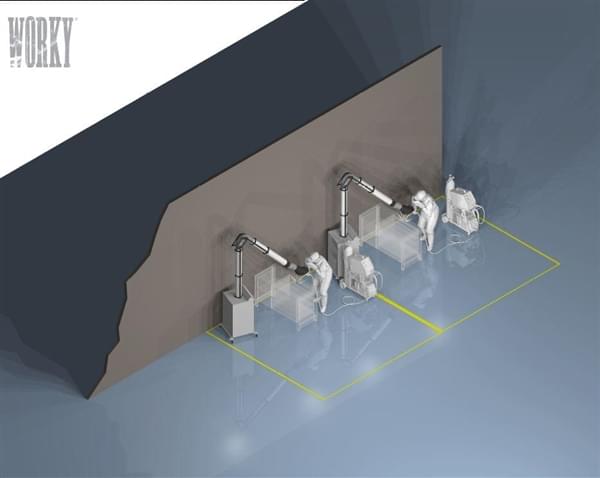

Trolley exhaust systems

A mobile fume extractor is a trolley-mounted filter with an articulated arm, easily transportable from one area of the workstation to another. After being extracted, fumes are filtered and then re-emitted into the work environment.

There are various models:

- with 1.5 HP or 3 HP extractor

- with bag filters or cartridge filters

Localised extraction is a duty and necessity

There are many advantages to using the right fume extraction system:

- healthier work environment

- multiple areas, even if located in different points of the same work environment, can be equipped with a dedicated extraction point

- as a consequence, production is leaner and more efficient.