The benefits of having an automatic lubrication system at your workshop

WORKY designs and manufactures automatic lubrication systems for workshops, body shops and all car and motorbike repair centres.

The ideal configuration involves two types of automatic systems, which interact with each other:

- Pumping automatic systems - for pumping and controlling fluid levels;

- Dispensing automatic systems - for delivering fluids and energy.

On this page you will find all the info about WORKY automatic and centralised lubrication systems, and the individual products from which they are composed: oil rooms, multifunctional structures, nozzles, reels and QUADRA Advanced Monitoring, our advanced monitoring system to be integrated into your system:

- How to design automatic lubrication systems

- QUADRA Advanced Monitoring: WORKY’s automatic system monitoring

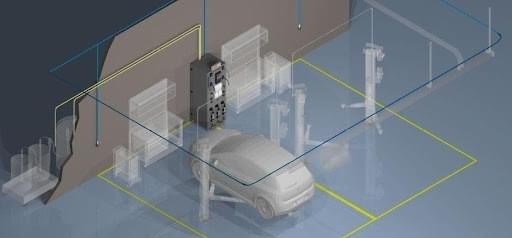

Design of automatic lubrication systems

Our automatic lubrication systems manage the flow of both new and used lubricating oils, as well as other technical fluids (antifreeze, windscreen washer, water, compressed air). Each centralised system is designed after a thorough inspection, on-site consultation and a precise and timely quotation.

The central lubrication system consists of:

- a central hub for the supply of fluids - from the RANGER with 3 reels to the MULTIPLE, a reinforced structure for supporting up to 10 hose reels;

- a central location for pumping the fluids - an oil room with various tanks and vats, equipped with anti-overflow indicators;

- bundles of pipes made of various materials, appropriately sized, to ensure a constant flow adapted to individual needs.

On request, an advanced automatic monitoring system can also be integrated.

Do you need an automatic lubrication system?

Ranger: a compact structure to house hose reels and electric sockets

Ranger, a structure for housing hose reels and sockets, is the most compact automatic lubrication system, designed for car and motorcycle workshops. It houses 3 reels for hoses up to 10 m long, 2 air or electric reels, 2 industrial sockets, 2 electrical sockets, 1 compressed air fitting.

FRMF metal structure

This is an essential metal structure, convenient yet functional thanks to the ability to house up to 6 10 or 15 metre reels and a helpful drip-tray tank. An encased version, FRMF-C, is also available.

MULTIPLO: a structure for supporting up to 10 hose reels

Multiplo is a reinforced structure for supporting up to 10 hose reels and is the best automatic fluid lubrication system for industrial workstations: it can house up to 8 15-metre fluid dispensing reels and 2 electrical cord reels. The advantage consists in the ability to connect a gas extraction hose and the availability of a workbench under the drip tray tank. It is also equipped with a container column that can house the grease barrel or used oil extraction pump.

QUADRA Advanced Monitoring: centralised automatic system monitoring

QUADRA Advanced Monitoring is our advanced system for monitoring automatic lubrication systems. A combination of solenoid valves, litre counters and software for managing the data of each individual fluid delivery makes it possible to cut down on waste and non-invoicing of hectolitres of oil.

Would you like to know more about our automatic lubrication systems and advanced monitoring system?

The ideal configuration involves two types of automatic systems, which interact with each other:

- Pumping automatic systems - for pumping and controlling fluid levels;

- Dispensing automatic systems - for delivering fluids and energy.

On this page you will find all the info about WORKY automatic and centralised lubrication systems, and the individual products from which they are composed: oil rooms, multifunctional structures, nozzles, reels and QUADRA Advanced Monitoring, our advanced monitoring system to be integrated into your system:

- How to design automatic lubrication systems

- QUADRA Advanced Monitoring: WORKY’s automatic system monitoring

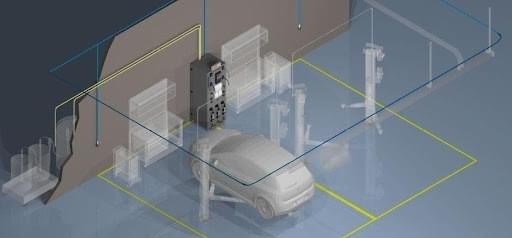

Design of automatic lubrication systems

Our automatic lubrication systems manage the flow of both new and used lubricating oils, as well as other technical fluids (antifreeze, windscreen washer, water, compressed air). Each centralised system is designed after a thorough inspection, on-site consultation and a precise and timely quotation.

The central lubrication system consists of:

- a central hub for the supply of fluids - from the RANGER with 3 reels to the MULTIPLE, a reinforced structure for supporting up to 10 hose reels;

- a central location for pumping the fluids - an oil room with various tanks and vats, equipped with anti-overflow indicators;

- bundles of pipes made of various materials, appropriately sized, to ensure a constant flow adapted to individual needs.

On request, an advanced automatic monitoring system can also be integrated.

Do you need an automatic lubrication system?

Ranger: a compact structure to house hose reels and electric sockets

Ranger, a structure for housing hose reels and sockets, is the most compact automatic lubrication system, designed for car and motorcycle workshops. It houses 3 reels for hoses up to 10 m long, 2 air or electric reels, 2 industrial sockets, 2 electrical sockets, 1 compressed air fitting.

FRMF metal structure

This is an essential metal structure, convenient yet functional thanks to the ability to house up to 6 10 or 15 metre reels and a helpful drip-tray tank. An encased version, FRMF-C, is also available.

MULTIPLO: a structure for supporting up to 10 hose reels

Multiplo is a reinforced structure for supporting up to 10 hose reels and is the best automatic fluid lubrication system for industrial workstations: it can house up to 8 15-metre fluid dispensing reels and 2 electrical cord reels. The advantage consists in the ability to connect a gas extraction hose and the availability of a workbench under the drip tray tank. It is also equipped with a container column that can house the grease barrel or used oil extraction pump.

QUADRA Advanced Monitoring: centralised automatic system monitoring

QUADRA Advanced Monitoring is our advanced system for monitoring automatic lubrication systems. A combination of solenoid valves, litre counters and software for managing the data of each individual fluid delivery makes it possible to cut down on waste and non-invoicing of hectolitres of oil.

Would you like to know more about our automatic lubrication systems and advanced monitoring system?