Industrial extractor for fumes and gas

WORKY manufactures fume and gas extraction systems for all the main industrial sectors where metal welding is regularly carried out. Depending on the frequency and intensity of the work, and on the configuration of the working environment, WORKY designs with you the best solution in terms of efficiency and functionality.

WORKY manufactures fume and gas extraction systems for all the main industrial sectors where metal welding is regularly carried out. Depending on the frequency and intensity of the work, and on the configuration of the working environment, WORKY designs with you the best solution in terms of efficiency and functionality.

Welding is one of the most common metalworking processes in different industrial sectors. It is in fact the basis for the creation of parts and components, but also complete and finished products. But welding is also an hazardous operations for workers' health, because the process releases a certain amount of pollutant toxic fumes. This is where an industrial extractor for fumes and gas come in.

Emissions released by metal welding

The toxic emissions produced during the industrial welding of metals are generated both by the fusion of the supporting metals with the sheet metal, both by the fusion of the parts together.

- One part consists of gases generated by the electric arc;

- One part of fumes and corpuscles produced by the actual melting;

- The last part of decomposition products of any coatings.

These aeriform exhalations, if inhaled, cause serious respiratory damage and not only; they can occur in the short term with acute symptoms and in the long term with chronic symptoms. It is therefore essential that the welding fumes and gas are extracted as soon as they are produced.

An industrial extractor for fumes and gas must act locally

To prevent fumes and gases from being dispersed into the working environment and inhaled, the industrial extraction system must act in a localized manner. That is, it must capture fumes and gases directly at the source. For this reason, all WORKY aspiration systems have articulated arms capable of reaching even the most difficult points in the workstation.

Given this, there are many different types of systems you can install depending on the requirements, i.e.:

- the type of industrial environment

- the frequency and intensity of welding work

- the number and layout of the workstations.

Types of WORKY welding fumes extraction systems

WORKY essentially proposes two lines of industrial extractor for fumes and gas: fixed and movable systems. Let's see how they differ.

FIXED SYSTEMS

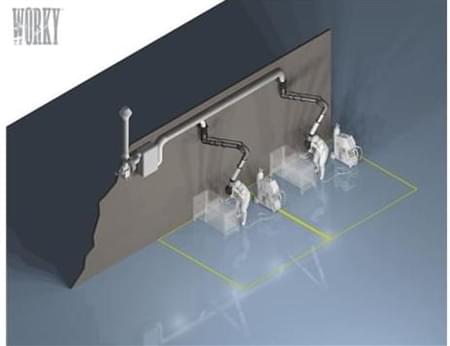

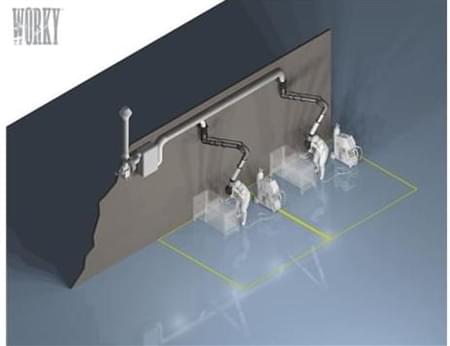

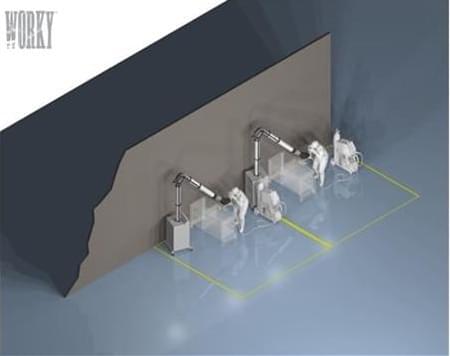

Fixed systems are all those systems that are permanently installed in the working environment. The suction unit is positioned at a strategic point in the work area. The arms reach the exact point where welding takes place, and suck in fumes and gases before they can spread into the place.

Fixed installations can:

- be designed from scratch, tailored to the size and requirements of the individual industrial environment.

- be made up of complete and ready to use kits (our SPARK KITs). They consist of wall mounted suction unit, extraction arm, filters for the re-injection of purified and deodorized air.

MOBILE SYSTEMS

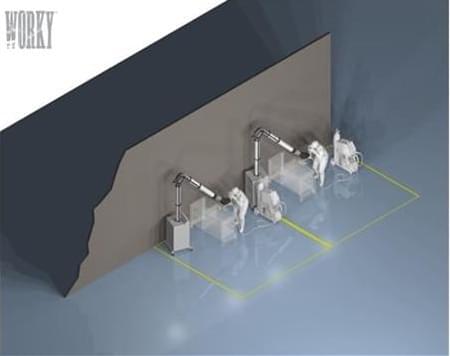

Mobile systems are all those trolley and portable fume extractor. Depending on the needs, a movable aspirator move from one workstation to another, extracting fumes and gas as soon as they are released.

WORKY trolley mounted filters are complete with aspirator, filters and articulated arm.

The importance of filters

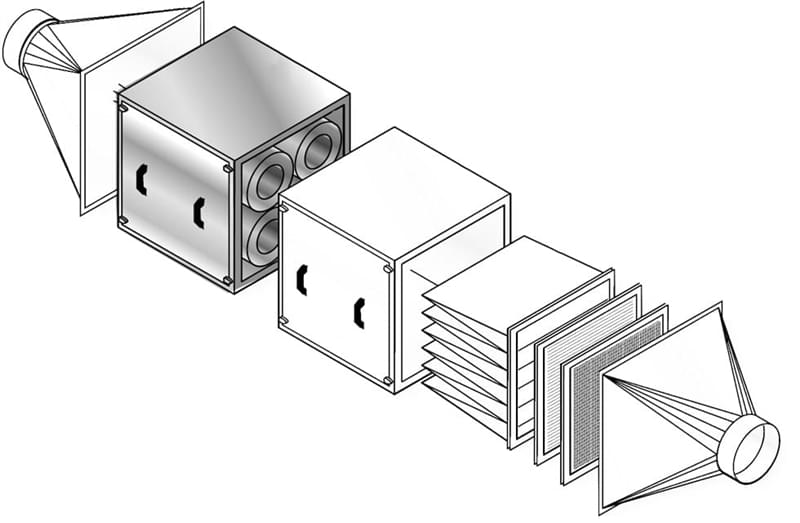

Generally, the air is filtered by the welding fumes extractors themselves, then deodorized and finally reintroduced into the working area. Only when it is not possible to reintroduce the air, you can install a chimney that expels them outside the factory.

For this reason, the filtering component is of fundamental importance. WORKY industrial fumes and gas extractors can be equipped with different types of filters:

- pocket filters, used to filter out welding fumes without large dust concentrations.

- cartridge filters, used instead to separate fumes from suspended dust.

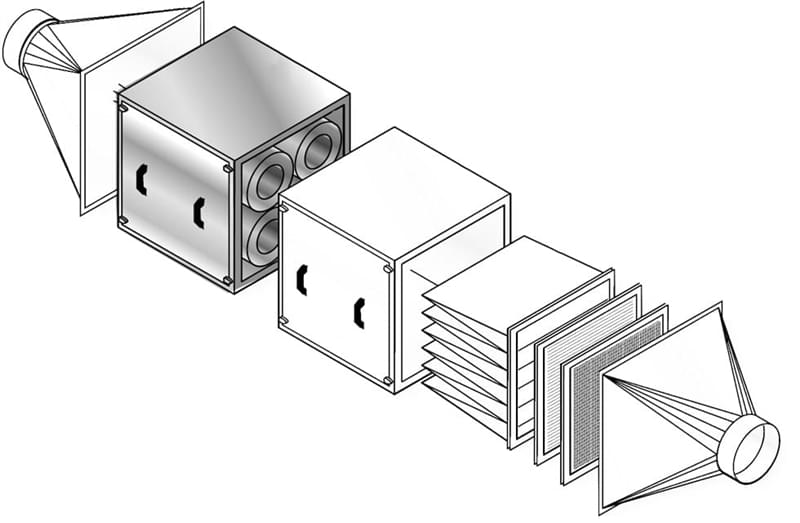

The air filtration systems always includes 4 filters: 1 metal fabric pre-filtering stage (spark extinguisher), 1 synthetic filter (for coarser particles), 1 high efficiency filter cell, 1 active carbon filter. The latter is an odor remover: it deodorizes the filtered air before putting it back into the environment.

On request, special filters (SPOL filters) can be installed, equipped with an automatic cleaning system for backwashing with compressed air. The aim is to keep the filter cartridges in perfect efficiency for longer.

Where to install an industrial extractor for fumes and gas

Our welding fume extraction systems meet the requirements of many different industrial environments every day. High quality applications include:

- manufactories

- mechanical workshops

- specialized laboratories

- carpentry, steelworks

- shipyards

- assembly lines.

They can, then, also meet less intense needs, such as those of simulation laboratories or schools (technical centers, professional institutes, etc.).

Do you want to know more about industrial extractor for fumes and gases by WORKY? Feel free to contact our sales department: we are always available to provide you the information you need.

WORKY manufactures fume and gas extraction systems for all the main industrial sectors where metal welding is regularly carried out. Depending on the frequency and intensity of the work, and on the configuration of the working environment, WORKY designs with you the best solution in terms of efficiency and functionality.

Welding is one of the most common metalworking processes in different industrial sectors. It is in fact the basis for the creation of parts and components, but also complete and finished products. But welding is also an hazardous operations for workers' health, because the process releases a certain amount of pollutant toxic fumes. This is where an industrial extractor for fumes and gas come in.

Emissions released by metal welding

The toxic emissions produced during the industrial welding of metals are generated both by the fusion of the supporting metals with the sheet metal, both by the fusion of the parts together.

- One part consists of gases generated by the electric arc;

- One part of fumes and corpuscles produced by the actual melting;

- The last part of decomposition products of any coatings.

These aeriform exhalations, if inhaled, cause serious respiratory damage and not only; they can occur in the short term with acute symptoms and in the long term with chronic symptoms. It is therefore essential that the welding fumes and gas are extracted as soon as they are produced.

An industrial extractor for fumes and gas must act locally

To prevent fumes and gases from being dispersed into the working environment and inhaled, the industrial extraction system must act in a localized manner. That is, it must capture fumes and gases directly at the source. For this reason, all WORKY aspiration systems have articulated arms capable of reaching even the most difficult points in the workstation.

Given this, there are many different types of systems you can install depending on the requirements, i.e.:

- the type of industrial environment

- the frequency and intensity of welding work

- the number and layout of the workstations.

Types of WORKY welding fumes extraction systems

WORKY essentially proposes two lines of industrial extractor for fumes and gas: fixed and movable systems. Let's see how they differ.

FIXED SYSTEMS

Fixed systems are all those systems that are permanently installed in the working environment. The suction unit is positioned at a strategic point in the work area. The arms reach the exact point where welding takes place, and suck in fumes and gases before they can spread into the place.

Fixed installations can:

- be designed from scratch, tailored to the size and requirements of the individual industrial environment.

- be made up of complete and ready to use kits (our SPARK KITs). They consist of wall mounted suction unit, extraction arm, filters for the re-injection of purified and deodorized air.

MOBILE SYSTEMS

Mobile systems are all those trolley and portable fume extractor. Depending on the needs, a movable aspirator move from one workstation to another, extracting fumes and gas as soon as they are released.

WORKY trolley mounted filters are complete with aspirator, filters and articulated arm.

The importance of filters

Generally, the air is filtered by the welding fumes extractors themselves, then deodorized and finally reintroduced into the working area. Only when it is not possible to reintroduce the air, you can install a chimney that expels them outside the factory.

For this reason, the filtering component is of fundamental importance. WORKY industrial fumes and gas extractors can be equipped with different types of filters:

- pocket filters, used to filter out welding fumes without large dust concentrations.

- cartridge filters, used instead to separate fumes from suspended dust.

The air filtration systems always includes 4 filters: 1 metal fabric pre-filtering stage (spark extinguisher), 1 synthetic filter (for coarser particles), 1 high efficiency filter cell, 1 active carbon filter. The latter is an odor remover: it deodorizes the filtered air before putting it back into the environment.

On request, special filters (SPOL filters) can be installed, equipped with an automatic cleaning system for backwashing with compressed air. The aim is to keep the filter cartridges in perfect efficiency for longer.

Where to install an industrial extractor for fumes and gas

Our welding fume extraction systems meet the requirements of many different industrial environments every day. High quality applications include:

- manufactories

- mechanical workshops

- specialized laboratories

- carpentry, steelworks

- shipyards

- assembly lines.

They can, then, also meet less intense needs, such as those of simulation laboratories or schools (technical centers, professional institutes, etc.).

Do you want to know more about industrial extractor for fumes and gases by WORKY? Feel free to contact our sales department: we are always available to provide you the information you need.