Welding fumes, released by the fusion between metals to be welded (and any deposit material), are, in fact, carcinogenic; fumes contain metal particles in the gaseous state and very fine particles, especially in the area near the welding point.

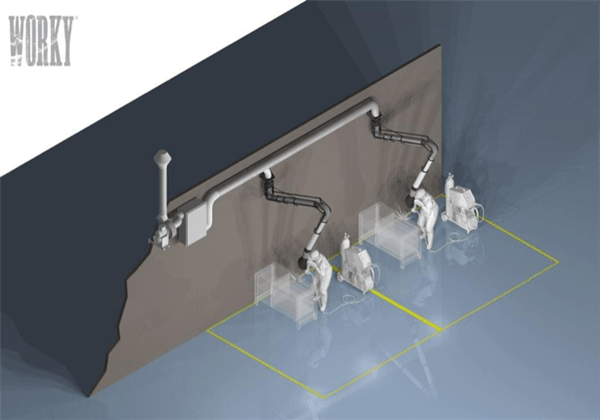

For this reason, it is essential for workshops or body shops to be equipped with fume extraction systems, able to capture emissions directly from the source before they are inhaled or dispersed in the atmosphere. WORKY designs and installs fixed systems, permanent, to extract fumes: you can choose a complete system, a ready-made kit or single parts.

Design a fixed fume extraction system

WORKY is able to provide various types of solutions. The fume extraction system is designed from scratch, based on your needs; the design takes into account the size of the centre, its layout, the number of workstations and their layout, the amount of welding work.

Fume extraction systems are made up of various elements:

- In the work area, extraction benches, fixed arms or sliding on extruded aluminium ducts

- Filters (pocket or cartridge)

- Properly dimensioned extractors

- Galvanised sheet metal coiled connection and exhaust hoses

Fume extraction kits

For body shops or workshops where welding is limited to a set and permanent area, we offer wall kits: these are complete fume extraction systems made up of an arm, a wall extractor and a pocket filter to clean and deodorise air with active carbon before reintroducing it in the room.

- The SPARK model has a spark retardant filter, a synthetic pre-filter, a main filtering cell with 5 kg of active carbon to deodorise the air;

- The SPARK-10 model, on the other hand, has a 10 kg active carbon cell, specifically designed for those regions where parameters are set by reference standards.

The benefits of our fume extraction systems: extractor arms

Many of our fume extraction systems for workshops or body shops include the installation of high quality extractor arms; the arms, available in a rigid (SB) and flexible version (SBF line), can be installed on the ceiling, wall or in a sliding version on an aerial duct.

The main features that provide high performance and make them able to adapt to any situation are:

- Hinges or joints that allow them to be moved to any position and remain stable in the chosen one;

- The variety of lengths (from 3 to 9 metres) and diameters (150 or 200 mm) that always allow the right point to be reached with the appropriate flow.

- Thrust bearing for 360° rotation

- A series of accessories: the wall bracket as well as an integrated air-lock shutter

- What's more, a lighting kit can be installed in the hood and hermetic lock with automatic shutter.

Solely combined with an extraction motor, they create a compact fume extraction system, highly convenient on the economic level.

Do you want to learn more about our fume extraction systems?