Anyone who works in a car body repair shop knows only too well that sanding is one of the key processes in bodywork repairs, essential for preparing the vehicle for painting. All the sanding methods used today however have one common problem: they produce dust. Hence the need to use efficient dust extraction systems, able to remove at the source what is a serious issue for health and productivity.

What are the main types of dust extraction system available on the market?

In today’s article we’ll take a look at the most common models, as well as the reasons behind opting for one type rather than another: choosing the best dust extraction system does in fact depend on the specific needs of each business.

In general, dust extraction systems can be divided into two categories:

Moveable systems: a moveable dust extraction system is the ideal solution for extracting sanding dust generated in different places each time, working with the utmost flexibility and ease of use. If for example you have very flexible layout in your body repair shop, a moveable dust extraction system will be able to follow you around, guaranteeing immediate removal of dust at the time you are working.

Moveable systems: a moveable dust extraction system is the ideal solution for extracting sanding dust generated in different places each time, working with the utmost flexibility and ease of use. If for example you have very flexible layout in your body repair shop, a moveable dust extraction system will be able to follow you around, guaranteeing immediate removal of dust at the time you are working.

Having ascertained the convenience of a moveable system, the next step is to decide what type of product is best suited to the needs of your body repair shop. For light duty, a compact model will be sufficient, working for just a few hours each day; more intense use will instead require a more powerful and larger size model, able to be kept running continuously for several hours. In addition, let’s not overlook the quality of the dust produced: potentially explosive dust or particular types of metal dust will require an ad hoc system. In any case, a diligent and professional supplier will be able to guide you towards the best product for your particular body repair shop.

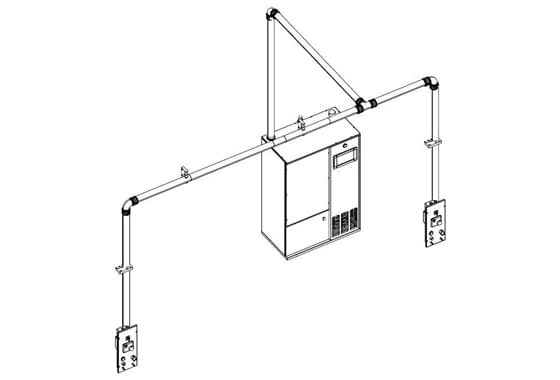

- Fixed systems: fixed dust extraction systems are recommended for use in body repair shops that want to increase their work volume, keeping the extraction level constant, but without having to take on increased system maintenance. The best dust extraction systems incorporate turbines that have blowers with side channels equipped with automatic systems for cleaning the filters, able to guarantee high performance that remains constant over time.

The way fixed dust extraction systems work is simple: the extraction turbine is connected via a system of aluminium pipelines to a service unit that provides centralised extraction in various work areas at the same time.

The way fixed dust extraction systems work is simple: the extraction turbine is connected via a system of aluminium pipelines to a service unit that provides centralised extraction in various work areas at the same time.

The orbital sanders used are fitted with flexible hoses that connect to the extraction system consisting of either arms, units or wall panels. The system is efficient and perfectly adaptable to the various areas where extraction is needed.