Exhaust extraction systems for heavy duty must be made with highly resistant components: pipes and vents, in particular, must withstand the high temperatures reached by the exhaust gases of these more powerful than normal vehicles.

Here's how WORKY can help heavy duty workshops to work in optimal conditions thanks to fixed and mobile solutions for exhaust extraction.

Fixed extraction systems

WORKY fixed exhaust extraction systems can be made with reels or with arms. A galvanized pipe conveys the emissions captured with the aid of an extractor, which can be integrated into the system or centralized to extract the exhaust gases from several points.

In addition to complete systems for exhaust extraction, we provide you with an assortment of individual components designed specifically for heavy vehicles. Let’s see a few examples.

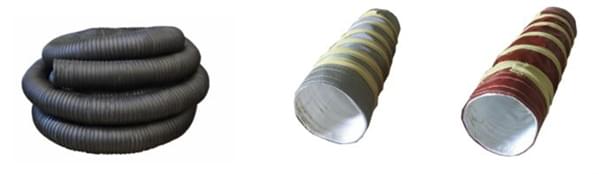

High resistance flexible hoses

WORKY has created 5 specific high-resistance hoses for truck exhaust extraction during maintenance: GT2 (400°F), GT3 (575°F), GT5 (930°F), GT7 (1300°F) and GT1 (1800°F).

- The GT2 flexible hose has a reinforced structure made of vulcanized rubber with a nylon spiral, and is suitable for maintenance operations with the engine idling;

- The other models are made of reinforced metal spiral fabric, suitable for withstanding the high temperatures reached by the gases emitted by heavy vehicles.

Depending on the model chosen, resistance up to 1800° F can be achieved.

Exhaust extraction nozzles

In addition to exhaust extraction hoses for trucks, the WORKY range has been enriched with a series of specific nozzles to adapt to different types of exhausts pipes on industrial and commercial vehicles.

Specifically, they can be used:

- for underbody units;

- for heavy duty;

- to reach exhausts placed behind the bumper and curved downwards;

- for high temperatures;

- for vertical exhaust pipes.

Learn more about high resistance components for truck exhaust extraction.

Mobile extraction systems

Mobile systems can also be used for heavy vehicle exhaust extraction, designed to adapt to the different positions of the mufflers.

GROLLY-T and GROLLY-V are WORKY's two mobile systems for exhaust extraction for heavy duty: designed for vans, trucks and buses, the two mobile systems have the necessary characteristics of resistance to high temperatures of exhaust gas and flow rates suitable for the exhaust pipes of large vehicles.

GROLLY-T: recommended for the exhaust extraction from trucks and buses

The motor power reaches 1.5 HP 400V three-phase, while the maximum flow rate rises to 2100 mc/h.

GROLLY-T is equipped with:

- Stainless steel nozzle;

- Tilting arm to move closer to the vehicle exhaust pipe;

- Built-in circuit breaker.

The product must be completed with the specific expulsion pipe: 393.7 inches long, 5.91 inches in diameter and PVC coated surface, resistant to a maximum temperature of 230° F.

GROLLY-V: recommended for the exhaust extraction from vans

It has a flow rate of 1700 mc/h and is composed of:

- A 1 HP motor;

- Rubber nozzle, designed not to scratch vehicle bumpers;

- Height adjustable structure (minimum 9.84 inches - maximum 29.52 inches);

- Installed start/stop switch.

The system must then be completed with the flexible hose to expel the exhaust gases outside the workshop; in the case of GROLLY-V, the ideal hose has a diameter of 5.91 inches and a length of 393.7 inches.

Request a personalized consultation with WORKY professionals: we will be able to recommend the best solution for your heavy duty workshop.