Are you looking for a monitoring system for oil or other technical fluids? In today's article we'll be introducing a very advanced and flexible monitoring system for technical fluid dispensing in the workplace: QAM, acronym for QUADRA Advanced Monitoring, one of WORKY's state-of-the-art solutions for fluid dispensing.

How does QAM work?

How exactly does QUADRA Advanced Monitoring work and what does it consist of? Let's find out together.

QAM consists of a series of electronic and mechanical parts assembled on oil distribution systems. The system can register the amount of fluid dispensed by each line, transmitting the data to a computerized system that keeps track of all quantities.

Whenever an operator needs a dispenser, the QAM oil monitoring system requires a series of steps, to obtain an unambiguous and accurate control of the amount of fluid dispensed:

- The operator gains access by means of a PIN, identity badge or by scanning in his or her personal bar code.

- After authentication, the operator keys in the job order, to which the dispensing is connected in a definitive manner.

- Once the job order has been connected, the operator has two choices of operation mode: free, if the amount of fluid to be dispensed is not pre-configured, or pre-configured, if the quantity has been determined beforehand. In any case, it's possible to top-up when the work is finished, and only the final quantity will be registered.

- Once the established amount of fluid has been dispensed, the operation is logged and saved in a database with all related data.

- If the DMS (company management software) allows it, it's also possible to pick these data from the database and create invoices directly connected to the acquired data, so as not to lose information and to invoice all the oil purchased.

Why use oil monitoring systems? As mentioned above, a system such as QAM allows for full control over the dispensing of all the fluids used in the workplace. Those who work in the sector are well aware of the fact that wasting oil (or other technical fluids) or failing to invoice them properly results in high wastage and loss of profit. every year. All of this is easily avoidable by investing on an oil monitoring system that pays itself off in a short time.

Monitoring modes

The best oil monitoring systems offer scalable solutions according to the size and needs of the workplace where they are installed. QUADRA Advanced Monitoring is no exception: this system is available in three different modes.

- Basic: In its basic mode, QAM consists simply of pistols with pre-selected amounts of fluid for dispensing. This simple control mode of dispensed quantities is suitable for oil and antifreeze.

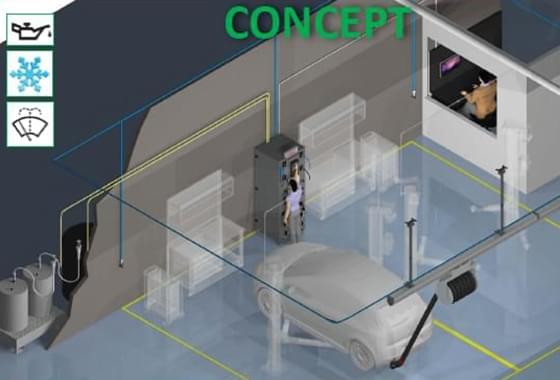

- Concept: In this mode, the distribution system is centralized. In this manner, it's possible to carry out all selection operations from a single work station, and to record the dispensing on a remote computer for digital monitoring. The Concept mode is suitable for the control of oil, antifreeze and windscreen washing fluid dispensing.

- Premium: In its most advanced mode, QAM is a centralized multi-direction system, perfectly integrated with the workshop's management software and invoicing system. In the Premium mode, QUADRA Advanced Monitoring monitors the dispensing, also simultaneously, of light and heavy oils, antifreeze, windscreen washing fluid, ADblue and grease, providing a complete and reliable service.

We'd like to wrap up this article by mentioning the Italian regulations for environmental protection, which requires the traceability of all the input and output values of all lubricating fluids. Oil monitoring systems such as QAM are an additional ally from the environmental point of view as well.

If you want to know more about the oil monitoring systems offered by WORKY, download our free catalogue and request a survey from our sales team!