The use of an effective vacuum system is the first step necessary to ensure a safe and clean work environment at auto body shops, where sanding dust can compromise the health of the workers, as well as the general productivity of the businesses.

There are currently various models of vacuum systems available, based on the specific needs of the auto body shops themselves. In general, the first major distinction to be made within the category of vacuum systems is between fixed systems and mobile systems, each of which is suitable for specific needs, the details of which have been previously discussed in this blog.

If you opt for a mobile vacuum system, the best units currently available on the market are equipped to effectively perform their functions without any special design features. The most efficient vacuum systems are extremely flexible, and can be integrated within various environments, while at the same time guaranteeing high levels of efficiency for vacuuming sanding dust: some of the best available solutions have been described in a previous article on mobile vacuum systems.

The fixed vacuum systems, on the other hand, require the layout to be carefully determined before selecting the configuration. In fact, during the design phase, it is recommended to determine the components to be utilized, based on the body shop's specific needs, in order to optimize their effectiveness.

With regard to fixed systems, it is recommended to evaluate the following aspects:

- The choice of the turbine most suitable for the types of activities to be performed: is it better to have a single or double blower turbine? Is an ATEX version required? Single blower turbines are suitable for conditions that require fixed suction power for up to 5 operators performing simultaneous sanding operations; double blower turbines allow for the turbine's power to be doubled whenever necessary, while at the same time guaranteeing excellent energy efficiency, thus rendering them ideal for greater power requirements. With regard to the ATEX version, this is required for vacuuming hazardous dusts, as required by the current ATEX regulations.

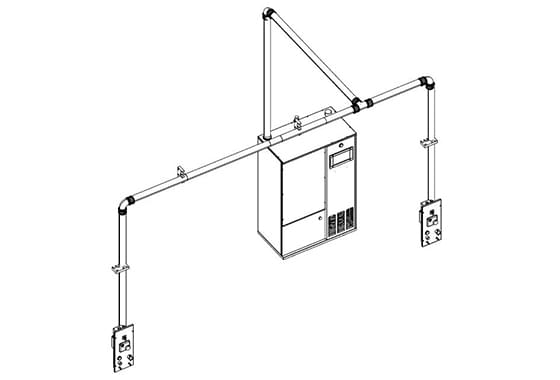

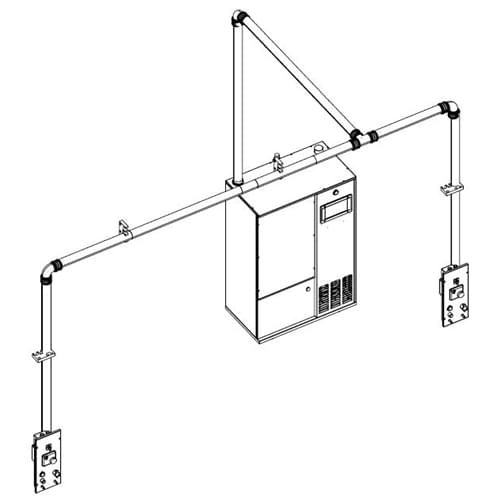

- Pipes: which are the best? For fixed vacuum systems, aluminium pipes are certainly the best solution, as they prevent the adhesion and accumulation of dust upon the interior surface of the pipe itself. Consult with a team of experts to evaluate the positioning and clamping of the pipe system at your auto body shop, in order to optimize the space in your work environments.

- The most suitable type of central unit: wall-mounted or ceiling-mounted? Integrated within the panels in the preparation area? In this case, the choice of the best solution once again depends upon the layout and the specific requirements of each body shop: it is therefore recommended to have technical experts conduct an on-site analysis of your specific needs.

- Vacuum systems with arms. The use of arms allows for exceptional flexibility with regard to the positioning of the electrical and pneumatic utilities and the suction openings, since they are capable of rotating 180 degrees. The ideal length of the arm should be evaluated in relation to the vacuum system's overall structure.

- The creation of an area for cleaning vehicles inside your body shop, thanks to a high-pressure reel system: in order to maximize order and efficiency, a cleaning system with a high-pressure reel system is ideal, as it allows for the hoses to be retracted and stored when not in use, thus eliminating encumbrances. The best reel systems currently available on the market are already equipped with hoses of variable lengths and diameters, based on the requirements, and can even be equipped with automatic activation devices.

Consult the Worky catalogue to find out more about the best available vacuum system components!